2015 Complete incinerator and waste-to-energy plant - 30,000 tons - Recovering the Irrecoverable

2015 Complete incinerator and waste-to-energy plant - 30,000 tons - Recovering the Irrecoverable

Location:Poland

Description

Impianto Inceneritore, Termovalorizzatore Completo

Produzione media 25.000 tonnellate di rifiuti annui, a seconda del potere calorifico dei rifiuti inceneriti, mentre l'impianto di solidificazione e stabilizzazione dei rifiuti, il centro di ricerca e il laboratorio, sono in grado di trattare oltre 100.000 tonnellate di rifiuti all’anno.

La Termovalorizzazione di questo impianto oltre alla produzione di energia elettrica pari a 3 MW è dedicata maggiormente al prodotto finale Granuli di Cemento

L'impianto può trattare una gamma molto ampia di rifiuti (centinaia di codici) di cui:

- Rifiuti da prodotto Agricolture

- Rifiuti industriali e Chimici

- Rifiuti Pericolosi e Farmaceutici

- PFU

- Scarto Legname

- Rifiuti Pericolosi Organici e non

- Car fluff

- Pulper di cartiera

- Materiale Organico vario

- Fanghi

- Rifiuto Liquido e inquinante

- Rifiuti derivati da vernice, smalti e inchiostri

- Rifiuti da industria siderurgica

- Liquame

- viscido

- Solventi Organici Alogenati

- Tanto Altro Ancora

Da certi gruppi di rifiuti viene creato un composto omogeneo e stabile

L'installazione prevede due processi nelle decisioni R1 e D10

Secondo la tabella ci sono diverse centinaia di codici.

Cioè praticamente tutto, tranne pietre, vetro e metallo pesante.

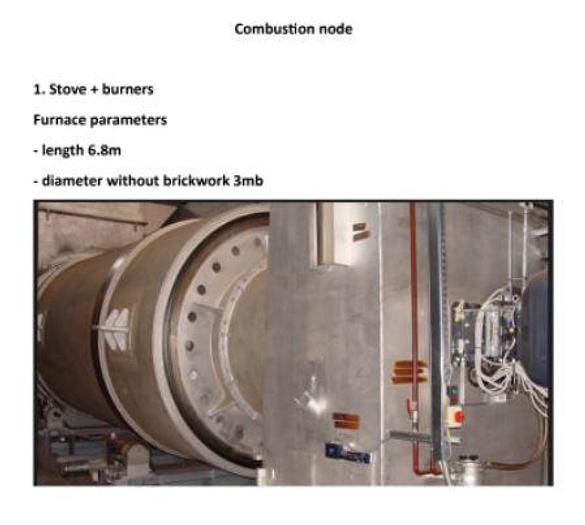

Impianto completo con postcombustione a due stadi di gas di scarico con temperature di oltre 1.100 gradi. Impianto avviato a fine 2015 e si presta inoltre per la combustione di rifiuti pericolosi, compresi rifiuti sanitari e quelli chimici industriali.

Comprende un metodo di trattamento completo dei rifiuti pericolosi per ottenere prodotti utili e un sistema di installazione che consente l'utilizzo di questo metodo all'avanguardia, protetto da brevetto.

La tecnologia prevede anche il trattamento dei rifiuti pericolosi e/o inorganici che dopo i processi di combustione, di solidificazione e stabilizzazione per trattare scarti come scorie e polveri ed ottenere, produrre aggregati artificiali come granuli di cemento ecc., che vengono poi utilizzati come aggregato artificiale nell'edilizia, nelle costruzioni di strade (asfalto) ed altro.

Ovvero la stabilizzazione e solidificazione di rifiuti inorganici pericolosi e non pericolosi, il cui prodotto finale saranno granuli di cemento.

Impianto certificato ISO 14001, certificato ISO 9001, ed altre certificazioni che coprono il recupero di rifiuti pericolosi e non pericolosi, con le migliori tecnologie emergenti in questo campo, test di laboratorio su rifiuti, acqua e liquami e con la produzione di aggregati artificiali utilizzando rifiuti.

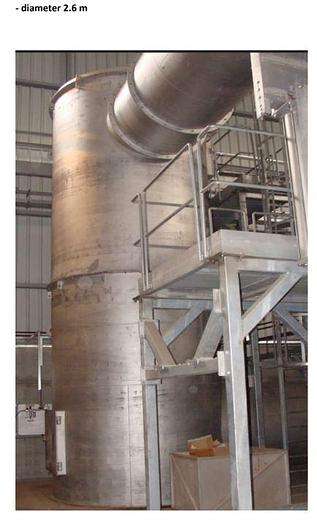

L'impianto si compone nei seguenti settori principali:

- Forno rotativo controcorrente con testata anteriore e posteriore,

- Dimensioni geometriche fondamentali del tamburo rotante: diametro esterno Dw – 3m - Lunghezza L – 7,9 mt - L/D 2.6 - Portata dei gas di scarico nel forno - Usp. – 1,85 m/sec. Tempo minimo di permanenza dei gas di scarico nel tamburo rotante - 4,2 sec. - Numero di giri del forno - 0,125 – 0,25 giri/min.

- Camere di postcombustione I e II collegate con connettori, con portata: QD = 60.000 m3/h

- Camere di miscelazione (raffreddamento fumi, dosaggio urea)

- Sistema di caldaie 13,2 TPH per la produzione di vapore surriscaldato con una capacità di 8.500 kg/h - 3,53 MPa - 30000 Nm3/h Si tratta di una caldaia a recupero di calore, a doppio giro, indipendente, monocilindrico a circolazione naturale.

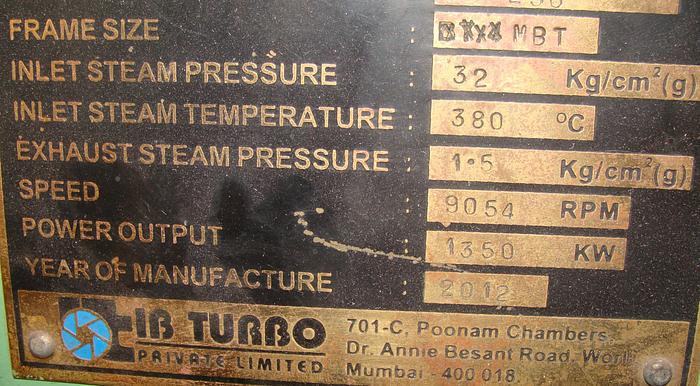

- Le Turbina con potenza di uscita di 1.350 kva e 2 generatori con potenza di uscita di 1.500 kva per totale 3 MW esistenti, non sono stati utilizzati perché per esigenze aziendali tutto il calore è stato sfruttato per essiccare la materia prima (per la grande richiesta) per la produzione di combustibili alternativi, quindi questo impianto turbina e Generatori sono praticamente inutilizzati (come nuovi).

- Sistemi di analisi elaborati da analizzatore GASMET CX-4000 - analizzatore JUM 3-700A - Ed altri

Disponibile tutta la documentazione riguardo il processo

- Impianto visibile in Est Polonia.

- Completo di tutti i documenti e certificazioni.

- L'offerta comprende lo smontaggio ed il carico.

- Disponibile Preventivo per Rimontaggio con avviamento e istruttoria,

- Azienda di grande competenza ci ha già fornito preventivo circa il rimontaggio dell'intero impianto, che metteremo a disposizione.

Specifications

| Year | 2015 |

| Condition | Used |